Executive Summary: A Paradigm Shift in Ceramic Manufacturing

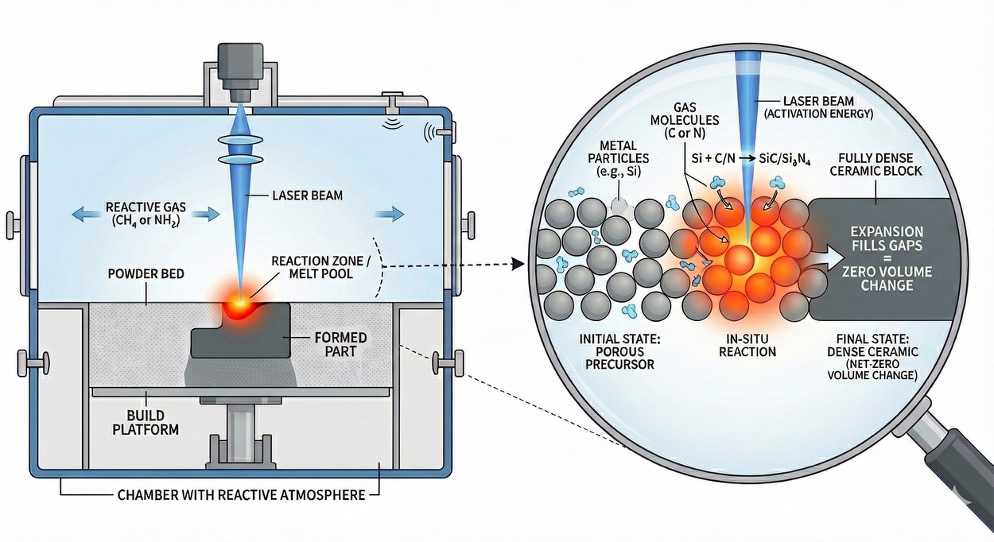

Selective Laser Reaction Sintering (SLRS) is an early-stage additive manufacturing (AM) technology poised to potentially disrupt the $5 billion global market for non-oxide ceramics. By enabling the direct, single-step synthesis of carbides and nitrides, SLRS solves the unmet need for manufacturing complex, net-shape components from extreme-environment materials like silicon carbide. Unlike traditional methods that rely on expensive diamond machining or binder-heavy printing processes, SLRS utilizes a reactive gaseous atmosphere to synthesize ceramics in situ with zero net volume change. This breakthrough technology has the potential to unlock new applications in electrification, defense, semiconductors, healthcare, and nuclear energy, allowing engineers to design parts and structures that were previously impossible to manufacture.

The Challenge: Limitations of Legacy Manufacturing

Non-oxide ceramics like silicon carbide and silicon nitride are currently used in demanding commercial applications such as aerospace turbine components, high-performance automotive brake discs, semiconductor manufacturing equipment, and orthopedic implants due to their exceptional thermal stability and hardness. The global supply of these critical components is currently dominated by incumbent manufacturers such as Kyocera, CoorsTek, and Saint-Gobain, who rely on established but geometrically limited sintering and machining processes. Current production methods for non-oxide ceramics force manufacturers to choose between material quality and geometric complexity.

- Conventional Fabrication (Sintering & Machining): Produces high-quality, dense parts but is restricted to simple shapes (plates, rods) due to the extreme hardness of the material, which makes machining prohibitively expensive and time-consuming.

- Traditional Ceramic Additive Manufacturing (Binder Jetting/SLA): Offers geometric freedom but relies on a multi-step process involving polymer binders. The subsequent de-binding and sintering steps cause significant linear shrinkage (15–20%) and volumetric shrinkage (>40%), leading to distortion, cracking, and low final densities that are unacceptable for mission-critical applications.

Market Context: The global market for non-oxide ceramics is projected to reach about $9 billion by the early to mid 2030s, creating a lucrative opportunity for a manufacturing platform that can deliver both complexity and performance without the legacy trade-offs.

The Technological Edge: “Zero-Volume Change” Synthesis

SLRS effectively repurposes the standard laser 3D printing process into a localized micro-chemical reactor. Instead of merely melting inert powder, the laser provides the activation energy to trigger a high-temperature chemical reaction between a “Reactive Net-Shape Precursor” powder bed and a reactive gas atmosphere (e.g., Methane or Ammonia).

How It Works

- Reactive Atmosphere: The build chamber is flooded with a reactive gas (e.g., methane for carbides) instead of an inert shield gas.

- In-Situ Synthesis: As the laser scans, it heats the metal precursor (e.g., silicon) to temperatures where it reacts avidly with the gas, instantly converting it into a ceramic (e.g., silicon carbide) while simultaneously sintering the particles into a solid layer.

- Net-Zero Innovation: The core differentiator is the precursor chemistry. By balancing the expansion of the metal component reacting with the gas against the shrinkage of the metal-oxide component, SLRS achieves a net-zero volume change. This allows for the 3D printing of dimensionally accurate, fully dense parts directly from the machine, eliminating the need for post-process sintering furnaces and binders.

Figure 1: Schematic of the SLRS process.

Comparative Analysis: Benchmarking Against Incumbent Technologies

To understand the disruptive potential of SLRS, it is essential to benchmark it against both conventional ceramic fabrication techniques and existing additive manufacturing (AM) modalities. SLRS occupies a distinct niche by addressing the unmet need for complex, dense non-oxide ceramics without the geometric and processing constraints of legacy methods. While Binder Jetting and Slurry Lithography have matured for oxide ceramics, they struggle with the material properties required for extreme environments—specifically regarding density and shrinkage.

| Feature | Binder jetting | Slurry lithography (SLA) | SLRS |

| Process mechanism | Liquid binder glues powder layer-by-layer. | Light cures photosensitive resin loaded with ceramic. | Laser triggers chemical reaction to synthesize ceramic. |

| Fabrication steps | Multi-step: Print → De-bind → Sinter | Multi-step: Print → De-bind → Sinter | Single-step: Reaction Synthesis + Sintering. |

| Volume change | High shrinkage (up to ~20% linear) causes distortion. | High shrinkage during de-binding; prone to cracking. | Near-zero volume change using a balanced reaction. |

| Purity & density | Often requires infiltration; lower density. | High density is possible but limited by resin burnout. | High purity; density tailored by reaction parameters. |

| Material focus | Oxides (Al2O3), infiltrated SiC. | Oxides, Si-based ceramics. | Non-oxide ceramics (e. g., carbides, nitrides). |

Defining the Niche: Where SLRS is NOT Competitive

While powerful, SLRS is not a universal solution for all ceramic manufacturing. To accurately assess the market opportunity, it is critical to acknowledge where the technology is not a viable replacement for existing methods:

- Oxide Ceramics: SLRS relies on carbothermal or nitriding reactions. It is inherently unsuitable for producing standard oxides like alumina or zirconia, which dominate medical and dental applications.

- Simple, Mass-Produced Parts: For simple geometries like wear tiles, standard cutting tools, or armor plates where internal complexity is unnecessary, traditional pressing and sintering remain far more cost-effective due to economies of scale and established supply chains.

- Large Monolithic Structures: Due to current printer build volume constraints (e.g., 250 mm cube) and the challenge of maintaining uniform gas reaction kinetics over large areas, SLRS is less competitive for massive structural components compared to near-net-shape casting or pressing.

- Ceramic matrix composites (CMC): SLRS produces monolithic (solid) ceramics. It lacks the ability to integrate the continuous ceramic fibers required for CMCs, which are essential for applications requiring high fracture toughness and resistance to catastrophic failure.

Material Performance Spotlight

The ultimate value of SLRS lies in its ability to produce ceramic parts that match or exceed the properties of traditionally manufactured counterparts while eliminating their geometric constraints.

- Density & Microstructure: SLRS achieves densities exceeding 99% of the theoretical maximum for materials like silicon carbide and hafnium carbide, rivaling hot-pressed ceramics. Unlike binder jetting, which often results in residual porosity requiring infiltration, SLRS creates a fully dense, monolithic structure directly from the melt pool.

- Mechanical Strength: Preliminary data indicates that SLRS-printed carbides maintain their exceptional hardness (e.g., ZrC ~25 GPa) and flexural strength even at elevated temperatures. The reactive nature of the process ensures strong inter-particle adhesion without the weak glassy grain boundaries found in liquid-phase sintered ceramics.

- Thermal Performance: Parts exhibit the intrinsic high thermal conductivity of non-oxide ceramics (e.g., SiC ~120-170 W/m·K), which is critical for various applications such as power electronics heat exchangers.

Potential Strategic Growth Verticals

The commercial adoption of SLRS is not driven by novelty, but by urgent technical bottlenecks in high-performance sectors where traditional materials have hit their limits.

1. Electrification & Power Electronics

The Market Driver: The global shift to 800V+ electric vehicle (EV) architectures demands silicon carbide semiconductors to handle higher voltages. However, current planar (2D) ceramic substrates create a thermal bottleneck, limiting power density and charging speeds.

- The SLRS Solution: SLRS enables the fabrication of 3D architected dielectric silicon carbide power modules with integrated, active cooling channels.

- Strategic Impact: These volumetrically efficient designs can reduce power module size by 60% and improve heat transfer by 50%. This directly translates to extended EV range and , positioning SLRS as a critical enabler for the next generation of electric mobility.

2. Hypersonics & Space Defense

The Market Driver: As defense sectors accelerate the development of hypersonic vehicles (Mach 5+), components must survive surface temperatures exceeding 2000°C. Standard superalloys melt under these conditions, and traditional Ultra high temperature ceramic (UHTC) manufacturing cannot produce complex aerodynamic shapes.

- The SLRS Solution: SLRS is uniquely capable of printing UHTCs such as hafnium carbide and zirconium carbide into net-shape leading edges and nose cones.

- Strategic Impact: The process allows for the integration of transpiration cooling networks (internal micro-porosity) that sweat cooling gas to protect the vehicle structure. This geometric freedom, combined with the extreme melting point of carbides and nitrides, provides a decisive strategic advantage in sustained hypersonic flight.

3. Next-Generation Nuclear Energy

The Market Driver: The resurgence of nuclear power, specifically Small Modular Reactors (SMRs) and Molten Salt Reactors (MSRs), requires structural materials that remain chemically inert over extended durations in highly corrosive, radioactive salt environments at high temperatures (>700oC).

- The SLRS Solution: The ability to print monolithic, chemically pure carbides (like chromium carbide) without the oxide binders found in traditional ceramic AM offers a new pathway for manufacturing reactor core linings and heat exchangers.

- Strategic Impact: SLRS components resist the rapid corrosion that degrades conventional alloys in molten salts. Furthermore, the tool-less nature of the platform enables a digital warehouse model, allowing operators to print critical replacement parts on-demand, bypassing the multi-year lead times typical of nuclear supply chains.

4. Industrial & Biomedical Resilience

The Market Driver: Supply chain fragility and the need for personalized care are driving a shift toward localized, agile manufacturing in both industrial processing and healthcare.

- The SLRS Solution:

- Medical: Printing silicon nitride spinal cages with engineered lattice structures that mimic human bone porosity to accelerate osseointegration.

- Industrial: Rapid fabrication of custom, wear-resistant tantalum carbide nozzles and valve seats for aggressive chemical processing.

- Strategic Impact: By eliminating hard tooling (molds/dies), SLRS reduces the cost of complexity, making low-volume, high-value production economically viable for specialized medical implants and industrial tooling.

Limitations and Challenges of SLRS

While SLRS represents a breakthrough in non-oxide ceramic manufacturing, it faces distinct challenges typical of an early-stage technology (TRL 4-5) moving toward industrialization.

- Safety and Engineering Controls: Using reactive gases like methane requires rigorous safety controls, including explosion-proof systems and specialized ventilation, adding operational complexity compared to standard inert-atmosphere printers.

- Process Stability and Scale: Achieving uniform chemical conversion in large parts is challenging; scaling requires precise thermal and atmospheric control to prevent unreacted powder and density variations.

- Throughput vs. Volume: While offering geometric freedom, SLRS has lower throughput than traditional forming, making it economically viable primarily for high-value, complex components rather than mass production.

- Part Size Maturity: While hardware supports large builds (250 mm), reaction uniformity across large sections remains unproven, positioning SLRS best for smaller, high-complexity components rather than massive structures.

Key Players and Ecosystem

The development and commercialization of SLRS is driven by a focused ecosystem of agile innovators, research institutions, and hardware enablers.

1. Startups

- Synteris (a Materic company): The primary commercial entity and technology pioneer behind SLRS. A Johns Hopkins Applied Research Lab spinout, Synteris holds the core intellectual property for the reactive synthesis process. They are currently focused on scaling the technology.

- Packet Digital: A key strategic partner and innovator in the power electronics space. They are collaborating with Synteris to design and integrate SLRS-printed ceramic heat exchangers into next-generation power modules for unmanned aerial vehicles (UAVs) and electric grids.

2. Academic and National Laboratories

- Johns Hopkins University Applied Physics Laboratory (JHU/APL): The birthplace of the core SLRS technology. JHU/APL continues to be a vital partner in fundamental material science research, supporting the validation of new carbide and nitride chemistries.

- National Laboratory of the Rockies (formerly National Renewable Energy Laboratory): A premier U.S. national lab providing critical testing and validation for SLRS applications in the energy sector. National Laboratory of the Rockies collaborates with Synteris on characterizing the thermal performance of 3D-architected SiC power modules to verify efficiency gains in electric vehicle powertrains.

- Lawrence Livermore National Laboratory (LLNL): A key strategic partner for defense-oriented material development. LLNL collaborates with Synteris under DARPA-funded initiatives to develop super-tough ceramic microstructures for extreme environments. They leverage their world-class capabilities in predictive modeling and non-destructive evaluation to optimize the reaction kinetics of SLRS, ensuring part reliability for mission-critical defense systems.

3. Equipment Companies

- Renishaw: Provides the open-architecture AM 400 platform, which Synteris retrofits for reactive gas safety. This leverages proven industrial hardware, enabling scalable production without the capital risk of developing proprietary printers.

Conclusion: The Future Trajectory of SLRS

SLRS represents a pivotal evolution in materials engineering, effectively transforming the 3D printer from a simple shaping tool into a localized chemical reactor. By successfully decoupling geometric complexity from processing constraints, SLRS solves the decades-old challenge of manufacturing fully dense, net-shape non-oxide ceramics without the debilitating shrinkage and binder limitations of legacy methods. This capability does not merely offer an incremental improvement over traditional sintering or binder jetting. It unlocks an entirely new design space where the extreme thermal and mechanical properties of carbides and nitrides can finally be exploited in complex, functionally optimized forms, from transpiration-cooled hypersonic structures to volumetrically efficient power modules.

As the technology matures from its current early-stage validation toward industrial scalability, SLRS is poised to become a critical enabler for next-generation extreme-environment systems. With the global market for ceramic additive manufacturing projected to grow at a CAGR of over 30%, the adoption of SLRS will likely be driven by high-value-added verticals—specifically defense, aerospace, and electrification—where material performance dictates market leadership. By enabling the on-demand production of mission-critical components that were previously unmanufacturable, SLRS is set to redefine supply chain resilience and establish itself as the standard for high-performance non-oxide ceramic manufacturing in the coming decade.

Recent Comments