This blog is based on our analysis – Oil and Gas (O&G) Automation Market, Global, 2024–2030, authored by Frost & Sullivan’s Growth Expert, Agustina DeSarriera, from the Power & Energy team.

The oil and gas automation ecosystem is undergoing a major transformation, projected to reach $32.08 billion by 2030, growing at a 7.4% CAGR. This evolution is driven by the need to improve operational efficiency, reduce emissions, and transition toward cleaner energy sources.

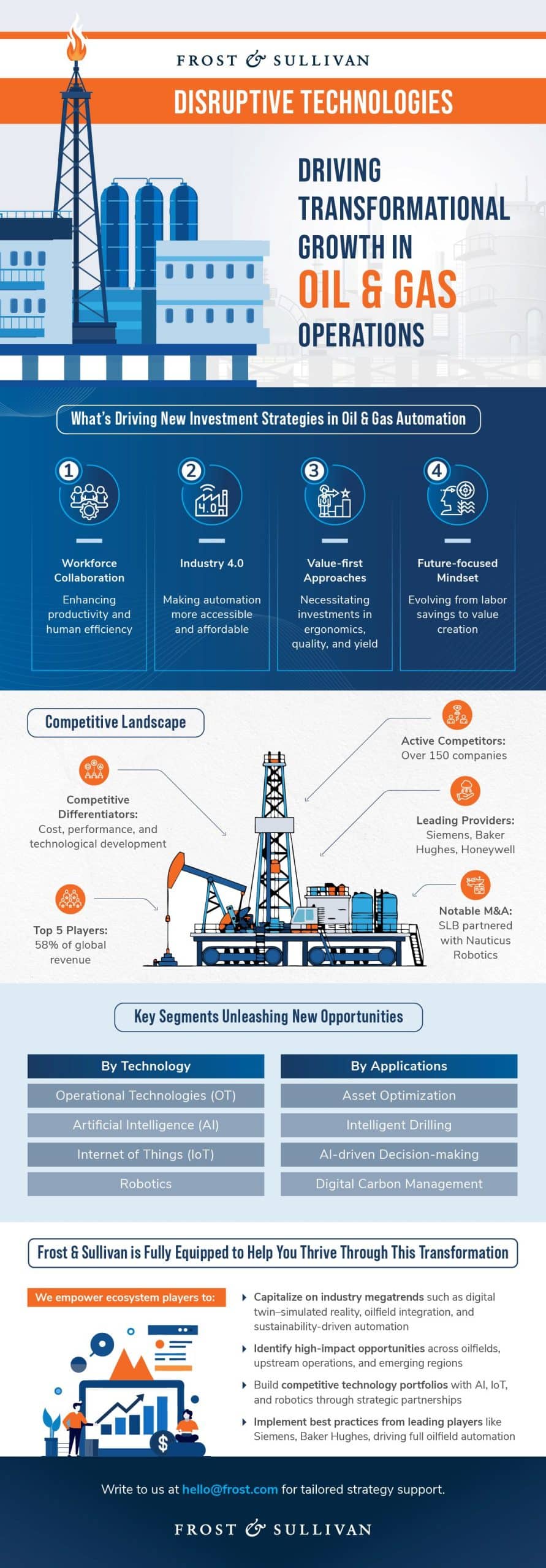

To meet these demands, companies are adopting AI-powered automation, Internet of Things (IoT)-enabled monitoring, and robotics to streamline workflows, optimize resource use, and enhance decision-making. These technological innovations are enabling operators to improve efficiency, safety, and sustainability, while unlocking new opportunities in a digitally connected energy landscape.

Explore how transformative megatrends, disruptive technologies, and internal challenges are redefining oilfield operation.

Is your operational strategy ready to integrate AI, IoT, and robotics across your oilfields?

Explore strategies to future-proof your oilfield operations.

Strategic Forces Revolutionizing Oilfield Automation

These three key forces are accelerating the adoption of automation in oil & gas:

- Transformative Megatrends: Sustainability and decarbonization are reshaping upstream operations, with Industry 4.0 enabling faster digital transformation.

- Internal Challenges: Conservative practices and reliance on traditional technologies are slowing the shift to advanced automation.

- Disruptive Technologies: AI, IoT, and robotics are augmenting human capabilities to improve safety, productivity, and real-time responsiveness.

Are you equipped with the right tools to capitalize on these transformative forces?

Oilfield Transformation at a Glance

Access the full analysis to identify growth areas and innovation hotspots.

Megatrends Shaping the Future of Oil and Gas Automation

As automation becomes foundational to next-gen oilfield operations, the following megatrends are setting the pace for innovation and competitiveness:

- Fully Autonomous Oilfields: AI, robotics, IoT, and digital twin technologies are enabling self-optimizing oilfields with minimal human intervention.

- AI-Powered Decision-making: Advanced analytics and machine learning models are driving real-time operational optimization and predictive insights.

- Hyperconnected Oilfields: IoT in oilfield operations is replacing siloed infrastructure, improving visibility, coordination, and asset performance.

- Sustainability-driven Automation: Intelligent systems are enhancing energy efficiency, reducing emissions, and achieving ESG compliance.

- Digital Twin Simulation: Virtual replicas of oilfield assets are enabling scenario testing, predictive planning, and safer decision-making.

Is your growth strategy aligned to leverage these automation megatrends?

Impact of Digital Technologies on Upstream Operations

These technologies are redefining upstream workflows and accelerating Industry 4.0 in the energy sector:

- Quantum Computing, Remote Sensing, IoT, Autonomous Systems, Digital Twins, Edge Tech: Revolutionizing oilfield operations and empowering companies to lead the next era of digital transformation.

- AI Decision-making, Sustainability Automation, Predictive Maintenance, Extended Reality (XR), Robotic Process Automation (RPA): Catalyzing digital transformation while maintaining operational competitiveness.

- Cognitive AI/Machine Learning (ML), Intelligent Drilling, Hydraulic Fracturing Automation, Optimization Tools: Offering niche-specific opportunities for small and medium-sized enterprises (SMEs).

Is your organization leveraging digital technologies to stay ahead in the evolving oil and gas ecosystem?

Companies to Action Leading the Automation Revolution

Global players are setting new benchmarks by integrating advanced technologies to optimize drilling, production, and decarbonization:

- SLB: Deploying AI-powered decision-making and digital twin technology to enhance drilling efficiency and predictive planning.

- Halliburton: Leveraging AI and cloud-based predictive maintenance platforms for real-time asset management and autonomous drilling.

- Baker Hughes: Integrating carbon capture and management technologies into digital oilfield solutions to drive intelligent decarbonization.

Do you have the right tools to benchmark performance and collaborate with innovators transforming upstream operations?

Regional Hotspots Driving Oil and Gas Automation Growth

From mature to emerging economies, regional O&G automation dynamics dictate where providers can maximize growth potential:

- Europe (17% → 20%): Fastest-growing region, expanding its share through strict environmental regulations and offshore projects.

- APAC (27.2%): Holding steady as the second-largest region, driven by rising energy demand and R&D investments in robotics and AI.

- North America (31% → 30%): Leading globally despite a slight decline, focusing on AI predictive maintenance and optimization.

- LATAM (11%): Maintaining its position with growth supported by exploration projects and digital infrastructure development.

- MEA (14.5% → 13%): Experiencing a gradual decline but continuing investments in automation technologies and renewable energy projects.

Are you implementing best practices to maximize ROI across high-growth regions?

Leverage insights from top-performing regions to optimize operation.

Lucrative Growth Opportunities in Oil and Gas Automation

The evolution toward automated oilfields is unlocking high-impact opportunities powered by AI, IoT, and robotics. Key areas gaining momentum include:

- Fully Autonomous Oilfields

Emerging automation technologies are transforming traditional upstream operations, driving a shift from partial digitalization to complete automation. This evolution will deliver major improvements in efficiency, safety, and reliability. To make the transition successfully, providers are:

- Building digital strategies to integrate AI, robotics, and IoT into existing assets.

- Prioritizing infrastructure upgrades for compatibility with advanced automation systems.

- Collaborating with technology vendors to adopt interoperable and intelligent drilling solutions.

- Advanced AI Systems for Full Oilfield Automation

AI is becoming the most indispensable technology for achieving oilfield automation, driving efficiency and operational optimization. To capitalize on this opportunity, providers are:

- Developing AI-powered drilling optimization models and closed-loop control systems for automatic adjustments during operations.

- Creating advanced AI-driven software for production optimization and asset management to boost efficiency.

- Expanding predictive maintenance capabilities with real-time visualization to minimize downtime.

- Intelligent Drilling for Full Oilfield Automation

Intelligent drilling is emerging as a fundamental technology for oilfield operations, minimizing human intervention and enhancing safety. So, to capture full potential, oilfield technology vendors are:

- Expanding automation capabilities by integrating AI and robotics for autonomous drilling systems.

- Combining AI-powered drilling automation with closed-loop control for real-time adjustments.

- Developing robotic systems for end-to-end drilling, including platforms and pipe-handling.

How will you prepare your organization to capitalize on these growth opportunities?

Ready to Transform Your Upstream Operations?

The future of oilfield operations lies in intelligent automation. From predictive maintenance to autonomous drilling, the technologies and strategies outlined here offer a clear roadmap for growth. This is the moment to act, before traditional approaches fall behind in a rapidly evolving energy landscape.

What concrete actions will your organization take today to lead the transformation toward oilfield automation?

Get in touch with our Power & Energy Experts to identify high-impact opportunities and align your water strategy with regional leaders.

Alternatively, you can also write to us at [email protected].