This blog is based on the whitepaper Growth Opportunities in Advanced Manufacturing & Automation from Frost & Sullivan’s TechVision Advanced Manufacturing & Automation team. The whitepaper draws content from ten Technology Opportunity Engine (TOE) analyses published in 2025.

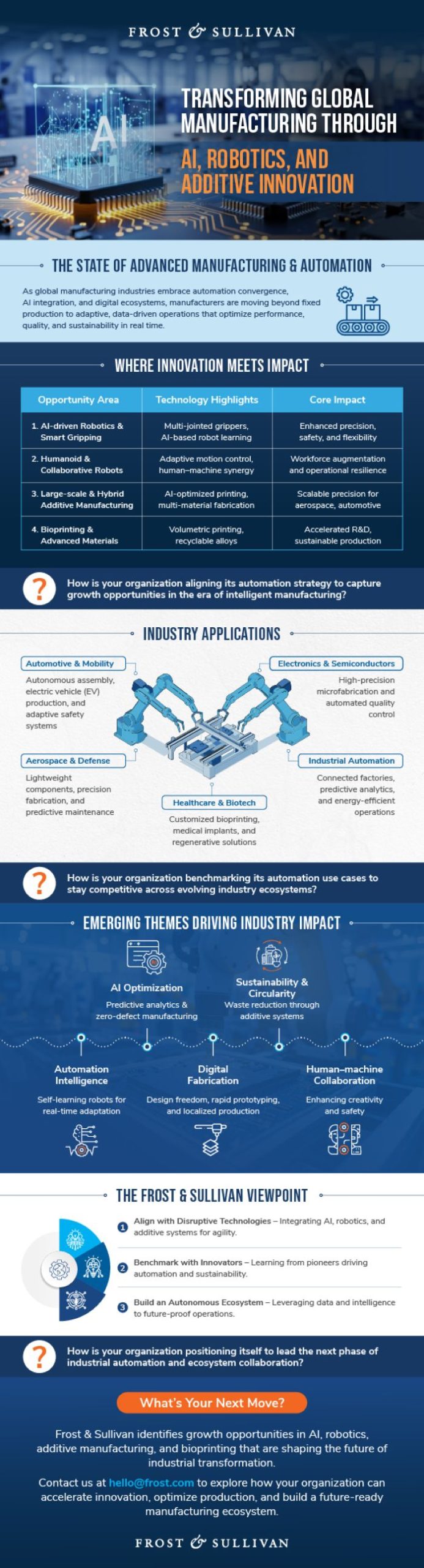

Global manufacturing is entering a transformative era where intelligence, agility, and sustainability are core drivers of competitiveness. The industry is moving beyond traditional programmed automation to self-optimizing, interconnected ecosystems that respond dynamically to demand, resources, and operational data.

Driven by breakthroughs in AI-enabled robotics, large-scale additive manufacturing, and bioprinting, this evolution is bridging the digital and physical worlds, enabling adaptive, low-carbon, and human-collaborative smart factories designed for the next generation of industrial growth.

Want to lead the next industrial revolution? Future-proof your manufacturing strategy with Frost & Sullivan’s expert analysis.

Frost & Sullivan’s latest whitepaper, Growth Opportunities in Advanced Manufacturing & Automation, identifies ten emerging opportunities areas where technology convergence and innovation are driving measurable performance and productivity gains.

How is your organization preparing to capitalize on these growth opportunities and position itself at the forefront of the autonomous manufacturing era?

Download the full whitepaper or connect with us at [email protected] to align your manufacturing strategy with future growth.

Key Technology Shifts Driving Advanced Manufacturing Innovation

AI-driven Robotics & Smart Gripping

AI-enabled robotics and intelligent multi-jointed grippers are enhancing precision, dexterity, and efficiency across complex industrial environments. From semiconductor assembly lines to heavy-duty material handling, these systems are enabling real-time responsiveness, safer operations, and continuous productivity gains.

Humanoid & Collaborative Robots

Humanoid robots and collaborative cobots are redefining workforce efficiency and human-machine synergy by collaborating safely with human operators. These robots are equipped with advanced motion control and AI perception systems to handle dynamic tasks and reduce operational downtime.

Large-scale & Hybrid Additive Manufacturing

Next-generation additive and hybrid manufacturing platforms are merging scale and precision. Hybrid systems, such as Breton’s Genesi LSAM (large-scale 3D printer), integrate additive and subtractive processes, enabling large-scale production with improved accuracy and reduced waste.

Bioprinting & Advanced Materials

Innovations in tomographic and light-based bioprinting are enabling rapid tissue and material fabrication for healthcare and aerospace applications. These systems deliver centimeter-scale printing in seconds, offering unparalleled customization and sustainability.

How is your organization aligning its automation roadmap to leverage these disruptive technologies for long-term manufacturing growth?

Strategic Imperatives Accelerating Growth in Advanced Manufacturing & Automation

Disruptive Technologies

From robotic intelligence and AI-based optimization to metal and bio-additive systems, disruptive technologies are enabling precision, flexibility, and autonomy across industrial processes.

Transformative Megatrends

Manufacturers are embracing sustainability, circular production, and connected ecosystems to meet the global demand for efficiency and environmental responsibility. The rise of Industry 5.0 is bringing together human creativity and robotic intelligence for a new era of collaborative productivity.

Innovative Business Models

The shift toward Automation-as-a-Service and AI-integrated production ecosystems allows companies to scale intelligently, reduce capital expenditure, and deliver agile, on-demand manufacturing solutions.

How is your organization aligning its strategy with these imperatives to capture emerging growth opportunities in manufacturing and automation?

Connect with us at [email protected] to align your growth strategy

Companies to Action: Leading Innovators Reshaping Manufacturing & Automation

Shengshu Technology (China)

A leader in AI-driven robot learning, Shengshu’s leverages a multi-view diffusion and inverse-dynamics model reduces training time and data needs, enabling rapid adaptation across robot types and accelerating industrial automation.

Tesollo (South Korea)

Tesollo’s DG-4F four-finger gripper features 18 joints and tactile sensing for high-precision handling. Its multi-mode design supports flexible, human-like manipulation across semiconductor, electronics and display manufacturing.

Breton (Italy)

Breton’s Genesi LSAM platform integrates additive and subtractive manufacturing with AI-based predictive maintenance, achieving output rates of up to 240 kg/hour. It delivers scalable, multi-material production for aerospace and automotive applications.

How is your organization benchmarking its automation strategy to stay aligned with the innovators driving intelligent and sustainable manufacturing transformation?

Access the Full Advanced Manufacturing Innovation Series to Discover More Key Players

Capturing the Future of Intelligent Manufacturing

The next four years will be pivotal for industries embracing automation, AI, and additive technologies. As manufacturing ecosystems are evolving toward intelligence and sustainability, organizations that invest in adaptability and innovation will be best positioned to capture emerging opportunities and shape future industrial growth.

Next Steps

Is your organization ready to turn industrial transformation into measurable growth?

Download the whitepaper or schedule a Growth Pipeline Dialog™ with Frost & Sullivan experts to strengthen your automation strategy and accelerate your path to intelligent manufacturing leadership.