This blog is based on the recent analyses, “Carbon Neutrality Strategies—Battery Electric Vehicles’ Carbon Footprint”, “Electric Vehicle Battery Value Chain, Global”, and “Strategic Analysis of Electric Motors for xEVs” authored respectively by Frost & Sullivan’s Growth Experts Federico Biscini, Jagadeesh Chandran, and Fatima-Zahra Essakhi from the Mobility team.

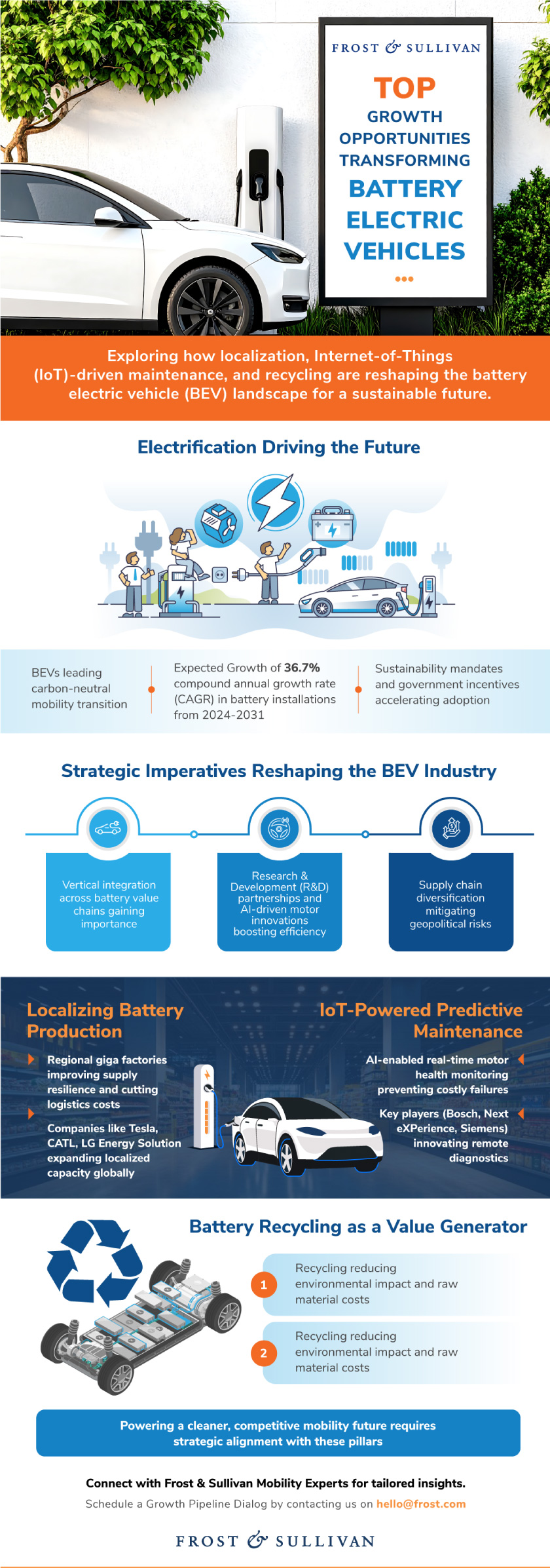

The world is shifting towards carbon-neutral mobility, and battery electric vehicles (BEVs) are leading the charge. Battery localization, predictive maintenance systems, and battery recycling are transitioning from niche strategies into industry imperatives, unlocking unprecedented growth opportunities. These innovations, powered by breakthroughs in solid-state batteries, sodium-ion chemistries, and AI-driven diagnostics, are redefining how vehicles are manufactured, serviced, and retired, while simultaneously reshaping global supply chains and competitive dynamics.

Governments worldwide are enforcing stringent sustainability mandates and providing substantial incentives to accelerate BEV adoption. Original equipment manufacturers (OEMs), battery suppliers, and technology innovators are responding with massive investments in vertical integration, advanced manufacturing, and circular economy practices.

Strategic Imperatives Shaping the Battery EV Industry

- Transformative Megatrends: Organizations are pursuing vertical integration across battery value chains to internalize production, reduce supplier dependency, and accelerate innovation in next-generation battery technologies.

- Competitive Intensity: Companies are strengthening R&D partnerships, scaling in-house innovation, and adopting AI-powered design to differentiate through superior motor performance and energy efficiency.

Geopolitical Chaos: Industry leaders are diversifying supply chains, implementing ethical mining practices, and building resilient, transparent ecosystems to shield operations from macroeconomic disruptions.

DID YOU KNOW?

Battery installation growth rate in 2024 was at 21%, which is expected to grow at a staggering 36.7% compound annual growth rate (CAGR) between 2024 and 2031.

Localizing Battery Production for Supply Chain Resilience

Global EV demand is surging, yet reliance on centralized battery production creates vulnerabilities. Localization is emerging as a strategic imperative, with OEMs establishing regional giga factories to enhance supply resilience, reduce logistics costs, and ensure regulatory compliance across key regions.

Companies to Action are Expanding Fast:

- Tesla is accelerating battery cell manufacturing in the U.S. and Europe through localized gigafactory expansions.

- Contemporary Amperex Technology Company Limited (CATL) is partnering with European automakers to establish near-demand cell plants, optimizing production costs.

- LG Energy Solution is investing in North American gigafactories to support major OEM commitments and reduce dependency on Asian suppliers.

IoT-powered Predictive Maintenance: Keeping Motors Running Longer

As EV powertrains evolve, traction motor reliability and performance have become critical success factors. IoT and AI-enabled predictive maintenance systems are revolutionizing how OEMs monitor motor health in real-time, detecting anomalies before they escalate into costly failures.

Ecosystem Players and Their Growth Strategies:

- Bosch is developing advanced predictive diagnostic tools that integrate motor control units with cloud-based analytics, enabling remote fault detection and extending motor lifespan across next-generation EVs.

- NXP Semiconductors is providing AI-powered sensor solutions for real-time performance tracking, vibration analysis, and predictive maintenance alerts in electric drivetrains.

- Siemens is leveraging digital twins and machine learning to optimize motor efficiency, reduce downtime, and enhance overall vehicle reliability through continuous monitoring.

Battery Recycling Is Turning Waste Into Value

Battery recycling has emerged as a cornerstone of EV sustainability, reducing environmental impact while creating a cost-effective alternative to virgin raw materials. As millions of EV batteries approach end-of-life, the recycling industry is attracting unprecedented investment, transforming from a compliance necessity into a competitive advantage.

Key players are scaling operations:

- Redwood Materials is partnering with U.S. OEMs to establish closed-loop recycling systems, recovering over 95% of critical battery materials.

- Fortum Oy is investing in battery recycling hubs across Europe, recovering valuable materials while significantly reducing the carbon footprint of new battery production.

Is your organization establishing itself as a closed-loop battery system provider to secure sustained revenue growth?

CLICK HERE to get access to the detailed analysis

Exploring How IoT-driven Maintenance and recycling are revolutionizing the BEV Landscape

Powering the Future of Mobility

From bustling urban centers to sprawling suburban networks, the electrification of transportation is reshaping supply chains, industries, and entire energy infrastructures. The convergence of advanced battery technologies, localized manufacturing, and circular economy practices is creating a vast, interconnected ecosystem, one that promises cleaner air, reduced emissions, and profound competitive opportunities for forward-thinking organizations.

What strategies is your company implementing to capitalize on the green mobility transformation and drive long-term growth?

Schedule a Growth Pipeline Dialog with our experts to strategize, innovate, and accelerate your EV initiatives for 2026 and beyond.

Want to dive deeper? Click here to connect with Federico Biscini, Jagadeesh Chandran, Fatima-Zahra Essakhi, and other mobility growth experts to discover how these insights can help you lead in the EV industry.

You can also connect with us at [email protected].