This blog is based on Frost & Sullivan’s analysis, “Non-Destructive Testing (NDT) Equipment Market, Global, 2024–2029,” and “Growth Opportunities for NDT in the Global Aerospace and Defense Industry, 2025–2029,” authored by Shruti Bapusaheb Yewale, and Ram Ravi from the Industrial Practice Area.

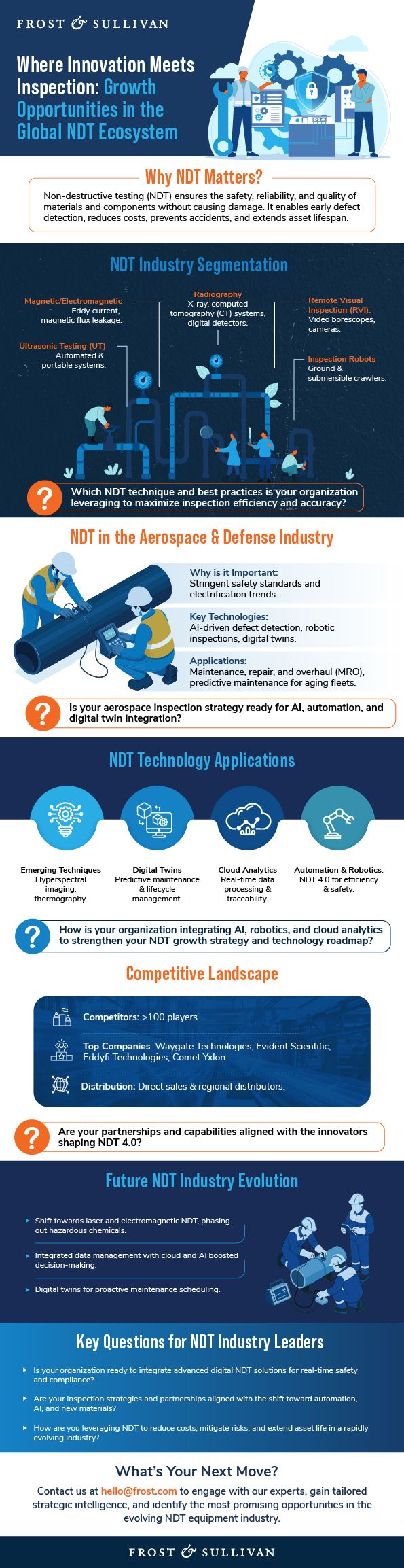

Industries worldwide are accelerating their digital transformation, and non-destructive testing (NDT) is evolving from a traditional quality control function into a strategic enabler of asset reliability, operational efficiency, and sustainability.

The transformation from manual, hardware-based inspections toward intelligent, data-driven systems is reshaping how manufacturers, utilities, and aerospace operators monitor performance, prevent failure, and ensure compliance.

Discover how the next generation of NDT inspection technologies, powered by AI, robotics, and digital twins, is redefining industrial reliability, efficiency, and safety.

According to Frost & Sullivan’s latest analysis, the global NDT equipment industry is poised for strong growth through 2029, supported by large-scale investments in aerospace and defense and power generation. Across all sectors, from automotive and electronics to oil and gas, the demand for inspection precision, faster testing cycles, and digital integration is accelerating.

Key Strategic Imperatives Shaping the Future of NDT

Innovative Business Models

- NDT companies are shifting from hardware-based revenue models to software-driven and subscription-based solutions that deliver recurring value.

- Advanced features such as data visualization, predictive diagnostics, and asset lifecycle management are becoming central to customer success.

- Smaller players are integrating digital platforms that enhance NDT equipment capability and improve overall cost-to-performance efficiency.

Industry Convergence

- The integration of dimensional metrology, AI, robotics, and NDT is transforming industrial quality control into a unified, data-rich ecosystem.

- Computed tomography (CT) systems are enabling precise, multi-dimensional insights throughout design, testing, and maintenance stages.

- Industry consolidation and cross-sector partnerships are expanding to deliver comprehensive asset integrity and quality solutions.

Transformative Megatrends

- Safety, sustainability, and workforce transformation are driving a fundamental shift in how industries approach inspection and operational excellence.

- The industrial metaverse is emerging as a powerful platform for immersive, risk-free training and practical skills development.

- Augmented reality (AR) and virtual reality (VR) tools are reducing human error and enabling remote collaboration across globally distributed operations.

How is your organization leveraging digital innovation and collaboration to stay competitive in the evolving NDT landscape?

Download our exclusive analysis to discover how NDT is redefining digital inspection.

Growth Drivers and Challenges

Growth Drivers

- The aging of global infrastructure is driving sustained demand for advanced NDT solutions to ensure the safety and longevity of pipelines, bridges, and power plants.

- Stringent regulations from agencies such as ISO, ASME, and OSHA are pushing organizations toward automated and standardized NDT inspection technologies.

- The growing use of composite materials in aerospace, automotive, and wind energy sectors is creating demand for specialized NDT methods capable of detecting micro-defects and delamination with high precision.

Key Challenges

- A shortage of skilled technicians remains a major bottleneck, especially as experienced professionals retire.

- The high cost of advanced NDT equipment limits adoption in emerging markets and small enterprises.

- Bridging the capability gap will rely on the integration of AI and cloud-based training platforms to develop digital and hybrid skill sets.

How is your organization addressing skill shortages and leveraging emerging technologies to turn infrastructure aging into an opportunity for NDT growth?

Growth Opportunities Reshaping the NDT Industry

Growth Opportunity 1: Industrial Metaverse and Workforce 4.0

Virtual training using AR/VR and simulation platforms is bridging the global skills gap in inspection. The industrial metaverse offers immersive, risk-free learning environments that enhance retention, reduce certification time, and enable global collaboration between experts and trainees.

Want to explore more NDT growth opportunities? Download the Full Analysis for Details

Best Practices for Success in NDT 4.0

- Software-Centric Models as the Next Growth Frontier

The NDT industry is moving from hardware dependency to software-enabled, service-based ecosystems. Integrated analytics and lifecycle intelligence are becoming essential for unlocking recurring value and sustaining long-term competitiveness.

- Industry Convergence for Value Creation

The intersection of AI, metrology, robotics, and cloud computing is transforming inspection into a connected, data-rich ecosystem. Strategic convergence is emerging as a key differentiator for organizations aiming to lead in NDT 4.0.

What best practices is your organization implementing to fully harness NDT 4.0 capabilities for smarter, faster, and more connected inspection processes?

Toward NDT 4.0: The Future of Intelligent Inspection

NDT 4.0 is transforming inspection from fault detection to intelligence creation. By integrating AI, Internet of Things (IoT), robotics, and cloud analytics, organizations are enabling real-time monitoring, predictive maintenance, and autonomous inspection.

This digital convergence is turning compliance into a strategic advantage, driving smarter, faster, and more sustainable operations. Companies that invest in connected ecosystems and data-driven testing are expected to lead the next wave of industrial resilience, where inspection, measurement, and manufacturing operate as one intelligent network.

Is your organization ready to lead the next wave of intelligent inspection?

Download the full analysis to accelerate your NDT growth roadmap

Next Steps

Connect with us at [email protected] or schedule a Growth Pipeline Dialog with our experts to kickstart your NDT growth journey.