Reflective of the intensifying need of industry to reduce its carbon footprint, Swedish mining company Boliden has announced a collaboration with Volvo Trucks to deploy two heavy battery electric trucks for underground transport operations at its mine in northern Sweden. The company claims that complete truck electrification in the mine could slash carbon emissions by nearly a quarter.

More overarchingly, this shift towards truck electrification represents a first step to realizing Boliden’s commitment to lowering carbon emissions – much of which is related to diesel vehicle usage – by 40% by 2030. It synchronizes with Volvo’s 2030 goal of ensuring that at least half of its new truck sales are electric by the end of the decade.

The use of Volvo’s trucks in Boliden’s mine will support a safer and more sustainable production environment. Boliden also claims that energy consumption will reduce as a result of the capture of electricity regenerated by the trucks’ electric drives. The Volvo Trucks-Boliden agreement will highlight how underground transport applications can effectively leverage environment-friendly, electric alternatives.

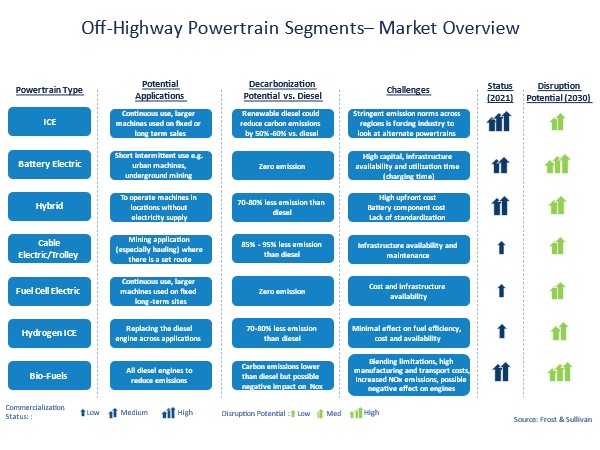

Off-Highway Powertrain Segment – Market Overview

To learn more about the major trends affecting the growth of the electric off-highway market, including sustainability initiatives, emission regulations, technology trends, market drivers & restraints, competitive factors, regional market share, and product launches, please see our forthcoming research report, Electric Off-highway Growth Opportunities or contact sathyanarayanak@frost.com for information on a private briefing.

Our Perspective

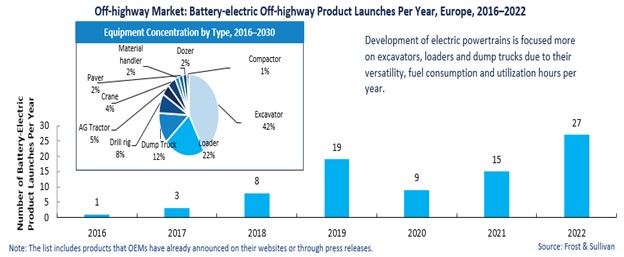

Frost & Sullivan anticipates accelerated adoption of electric equipment in the off-highway (OHW) market in the longer term. OEMs and key stakeholders are already beginning to establish a network of solutions that would enable easier integration of zero emission powertrains within the market. Volvo has been in the forefront of electric and autonomous equipment development, especially for construction and mining applications. The introduction of its FH Electric truck at Boliden’s Kankberg mine would allow the Swedish truck manufacturer to complement and further develop its mining specific electric autonomous trucks such as the HX2 and TA15.

In parallel with the increasing push towards sustainability, Europe and the Americas have emerged as key regions for developing and piloting zero emission technologies in mining. Caterpillar, Komatsu, Sandvik, Liebherr and Hitachi, among others, are leading OEMs currently developing hybrid and battery electric trucks, specifically for mining applications.

Off-highway Market: Battery-electric Off-highway Product Launches Per Year, Europe, 2016-2022

Simultaneously, mining operators are turning to joint ventures as they begin to embrace fleet electrification for open pit and underground operations.

Caterpillar cooperating with BHP to electrify mining dump trucks, LKAB trialing Sandvik’s battery electric truck and loader at an underground iron ore mine, and Codelco piloting Epiroc’s fully electric loader at its El Tiente copper mine are some of the several projects worldwide that are focused on electrifying mining operations.

With inputs from Amrita Shetty, Senior Manager – Communications & Content, Mobility